Any question, please contact us for free. Phone number: +86-371-86686767 Skype: zgboiler Email:zbgboiler@zzboiler.com

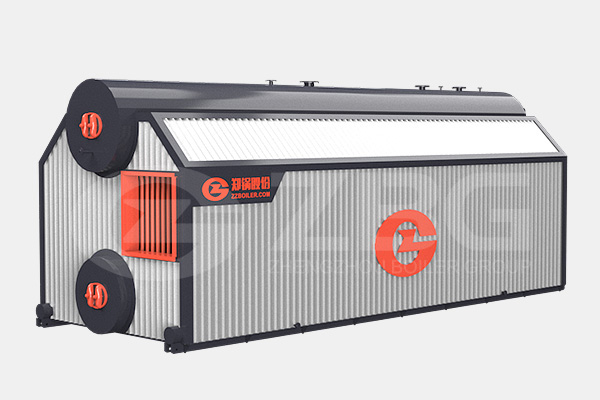

45 ton corner tube boiler exported to Costa Rica

Modelcorner tube biomass boiler

Capacity45 ton

Applicationproviding steam for industry

Overview

Biomass corner tube boiler main parameters:

Rated steam capacity: 45t/h

Rated steam pressure: 3.82Mpa

Rated steam temperature: 450℃

Feeding water temperature: 104℃

Design thermal efficiency: 87.5%

Fuel consumption: 10807Kg/h

Combustion type: layer combustion

Boiler safety operation range: 70%~100%

The designed fuel: peanut shell

Biomass fired corner tube boiler benefits

The boiler adopts self-supporting membrane water wall structure, which is national patent technology.

Using clean combustion technology to burn the fuel peanut shell for power generation.

Based on ZG Boiler’s experience of biomass boiler and corner tube boiler, the biomass corner tube boiler is designed to make itself optimized to a variety of biomass fuels with high efficiency.

The fuel peanut shell or other fuels burn, the ash and slag can be used as the agricultural fertilizer directly. It is efficient and environment friendly.

Strictly in accordance with ASME and ISO standards.

Background

Agriculture in Costa Rica is developing very fast. There are many biomass fuel available for industry. Compared to many boiler in the market, a company there ordered a corner tube type steam boiler from our company to provide high quality of steam for production.

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

RELEVANT CASES

RELEVANT PRODUCTS

-

DZL Packaged Boiler

Pressure:≤1.6MPa

Fuel:Wood, Rice Husk, Bagasse, Straw, Sawdust

Capacity:2-10 t/1.4-7 MW -

Biomass Power Plant Boiler

Pressure:≤5.29MPa

Fuel:Rice Husk, Straw, Wood Pellet, Bagasse

Capacity:10 - 75 t/ 7-52.5 MW -

SZL Water Tube Boiler

Pressure:≤1.6MPa

Fuel:Biomass Fuel, Rice Husk, Bagasses

Capacity:6-30 t/ 4.2-21 MW -

Biomass Fired CFB Boiler

Pressure:≤5.29MPa

Fuel:Biomass,Rice Husk,Palm Kernel

Capacity:20-280 t/ 14-196 MW

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

HOW TO CONTACT

-

E-mailzbgboiler@zzboiler.com

-

Tel0086-371-86686767

-

Fax0086-371-67838093

-

Skype17719993430

-

Whatsapp+86 17719888549

-

AddZhengzhou,Henan,China