Any question, please contact us for free. Phone number: +86-371-86686767 Skype: zgboiler Email:zbgboiler@zzboiler.com

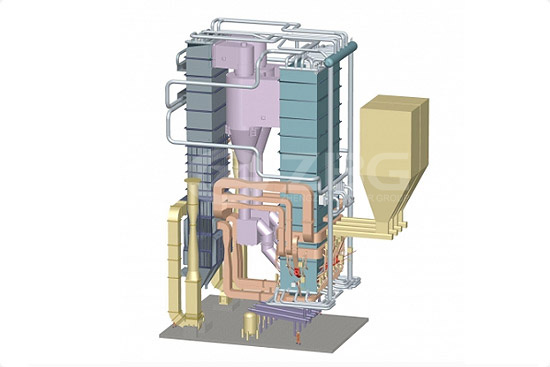

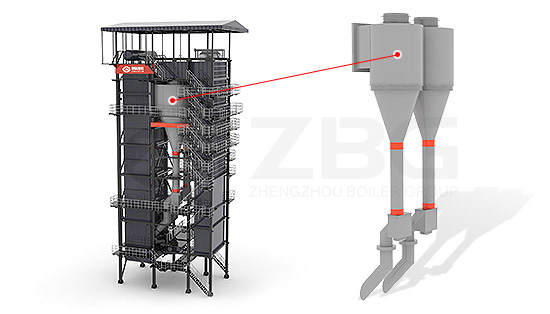

Biomass Fired CFB Boiler

Circulating fluidized bed biomass power plant boilers has owned the same advantages like other cfb boiler, such as high efficiency, good combustion performance, energy saving. Besides, it burns shaped biomass fuel, which can also provide heat or generate electricity purely use coal or mixture of coal and biomass fuel.

-

CAPACITY

20-280 t/ 14-196 MW

-

Pressure

≤5.29MPa

-

Fuel

Biomass,Rice Husk,Palm Kernel

-

Application

Power Plant,Central Heating,City Heating

Large furnace, low fuel costs

CFB biomass boiler have large combustion space and enough height to make sure the fuel have the sufficient time to burn in the furnace, meanwhile the adequate and stratified secondary air is deployed to fit in with the concentrated of volatile, so that guarantees the fuel and air are fully mixed to burn out in the furnace.

High combustion efficiency, cost savings

a. The suspension furnace equipped with the water-cooled wall and the inlet of separator is water-cooled flue duct make it less heat-releasing and boiler-efficiency improvement.

b. The separator and the center tube of loopback materials device have applied the technological improvements for low resistance, high separation efficiency, which ensure high combustion efficiency and low burn ash residual calorific value, savings cost.

Air preheater, avoiding corrosion

The air preheater use of a multi-tube box arrangement and low-temperature section use of corrosion-resistant steel to avoid the corrosion the parts by low temperature cause to replace the whole.

| Model | Rated Steam Capacity |

Rated Steam Pressure (bar) |

Rated Steam Temperature (℃) |

Rated Water Temperature (℃) |

Fuel Type | |

| t/h | BHP | |||||

| DHX15-1.25-T | 15 | 1149 | 12.5 | 194 | 105 | Coal, Tobacco stem |

| DHX20-1.25-AⅡ | 20 | 1532 | 12.5 | 194 | 105 | bituminous coal, Leather waste liquid |

| DHX35-1.25/230-T | 35 | 2681 | 12.5 | 230 | 105 | Brown coal, Distiller's grains |

| DHX35-1.25-W | 35 | 2681 | 12.5 | 194 | 105 | Anthracite coal |

| DHX35-1.25/300-P | 35 | 2681 | 12.5 | 300 | 105 | Lean coal |

| DHX35-1.6-AII | 35 | 2681 | 16 | 204 | 105 | Bituminous coal |

| DHX35-2.5/400-AII | 35 | 2681 | 25 | 400 | 105 | Bituminous coal |

| DHX35-3.82-A | 35 | 2681 | 38.2 | 450 | 105 | Bituminous coal |

| DHX40-4.2-W | 40 | 3064 | 42 | 254 | 105 | Anthracite coal |

| DHX45-1.6-H | 45 | 3447 | 16 | 204 | 105 | Brown coal |

| DHX50-2.5-W | 50 | 3830 | 25 | 226 | 105 | Anthracite coal |

| DHX65-2.5/250-H | 65 | 4979 | 25 | 250 | 105 | Brown coal |

| DHX75-1.6-P | 75 | 5745 | 16 | 204 | 105 | Lean coal |

| DHX75-2.5/350-P | 75 | 5745 | 25 | 350 | 105 | Lean coal |

| Model | Rated Steam Capacity | Rated Steam Pressure (bar) |

Rated Steam Temperature (℃) |

Feed Water Temperature (℃) |

Fuel Type | |

| t/h | BHP | |||||

| SHX4-1.25-A | 4 | 306 | 12.5 | 194 | 105 | Bituminous coal |

| SHX6-1.6-P | 6 | 460 | 16 | 204 | 105 | Lean coal |

| SHX8-1.25-T | 8 | 613 | 12.5 | 194 | 105 | Shaped biomass pellet |

| SHX8-2.5-H | 8 | 613 | 25 | 226 | 105 | Brown coal |

| SHX10-2.5/450-AII | 10 | 766 | 25 | 450 | 105 | Bituminous coal |

| SHX12-2.5-W | 12 | 919 | 25 | 226 | 105 | Anthracite coal |

| SHX15-2.5-A | 15 | 1149 | 25 | 226 | 105 | Bituminous coal |

| SHX20-2.5-W | 20 | 1532 | 25 | 226 | 105 | Anthracite coal |

| SHX25-2.5-AII | 25 | 1915 | 25 | 226 | 105 | Bituminous coal |

| SHX30-2.5/400-W | 30 | 2298 | 25 | 400 | 105 | Anthracite coal |

| SHX35-2.78/400-AII | 35 | 2681 | 27.8 | 400 | 105 | Bituminous coal |

| SHX45-1.25/300-AII | 40 | 3064 | 12.5 | 300 | 105 | Bituminous coal |

| SHX45-1.25/300-AII | 45 | 3447 | 12.5 | 300 | 105 | Bituminous coal |

| SHX50-2.5/400-H | 50 | 3830 | 25 | 400 | 105 | Brown coal |

| SHX65-1.25-A | 65 | 4979 | 12.5 | 194 | 105 | Bituminous coal |

| SHX75-1.6/250-AII | 75 | 5745 | 16 | 250 | 105 | Bituminous coal |

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

HOW TO CONTACT

-

E-mailzbgboiler@zzboiler.com

-

Tel0086-371-86686767

-

Fax0086-371-67838093

-

Skype17719993430

-

Whatsapp+86 17719888549

-

AddZhengzhou,Henan,China