Any question, please contact us for free. Phone number: +86-371-86686767 Skype: zgboiler Email:zbgboiler@zzboiler.com

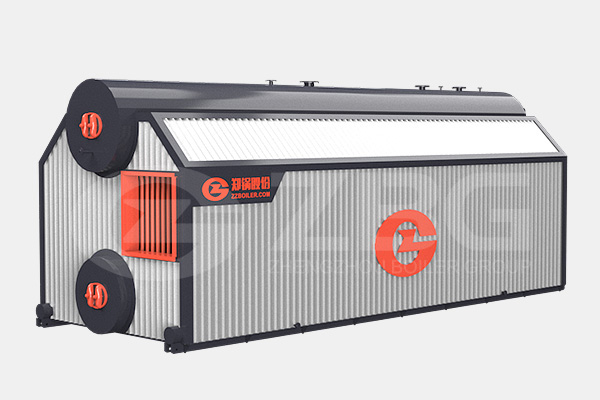

30 T/H Biomass Corner Tube Boiler Columbia

Modelbiomass corner tube boiler

Capacity30 ton

Applicationsteam for processing heat

Overview

Main parameters of biomass corner tube boiler

Model: ZG-30/3.82/330-T

Rated steam capacity: 30t/h,

Rated steam pressure: 3.82Mpa,

Steam temperature: 330℃

Fuel: 71% palm kernel fiber and 29% palm kernel shell

The biomass corner tube boiler burning palm kernel fiber & shell is a great challenge for my company. We had no idea about this kind of fuel before, while, we did many researches on the fuel analysis. With the supporting of our manager, salesman and technicians, we communicated with our customers actively, and finally we solved all the problems and signed the contract.

The palm kernel shell & fiber corner tube boiler was designed and manufactured strictly in accordance with the latest ASME standard. After the boiler was exported to Columbia, we also sent professional person for the site installation guidance until the project was completed.

Background

Biomass resources, including agricultural crop residues, forest residues, animal wastes, agro-industrial wastes, municipal solid wastes and aquatic biomass are used in industrial boilers as low cost and clean fuel to save cost for industries. Biomass fired boiler is more and more preferred by industry in recent years. We have exported a ZG-30/3.82/330-T biomass corner tube boiler to Columbia to provide steam for industry.

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

RELEVANT CASES

RELEVANT PRODUCTS

-

SZL Water Tube Boiler

Pressure:≤1.6MPa

Fuel:Biomass Fuel, Rice Husk, Bagasses

Capacity:6-30 t/ 4.2-21 MW -

Biomass Power Plant Boiler

Pressure:≤5.29MPa

Fuel:Rice Husk, Straw, Wood Pellet, Bagasse

Capacity:10 - 75 t/ 7-52.5 MW -

Corner Tube Biomass Fired Boiler

Pressure:≤5.29MPa

Fuel:Rice Husk, Wood Pellet, Bagasse

Capacity:10-160 t/7-112 MW -

DZL Packaged Boiler

Pressure:≤1.6MPa

Fuel:Wood, Rice Husk, Bagasse, Straw, Sawdust

Capacity:2-10 t/1.4-7 MW

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

HOW TO CONTACT

-

E-mailzbgboiler@zzboiler.com

-

Tel0086-371-86686767

-

Fax0086-371-67838093

-

Skype17719993430

-

Whatsapp+86 17719888549

-

AddZhengzhou,Henan,China