Requirements for the Design, Supply, Manufacture, Installation and Commissioning of an Auxiliary Boi

1.GENERAL REQUIREMENTS

1.1.Scope

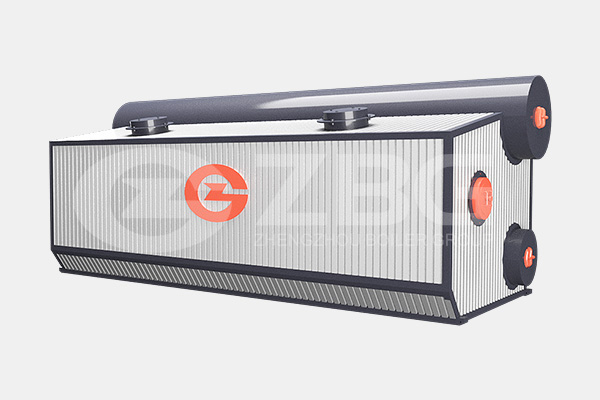

This specification covers the requirements for the design, supply, manufacture, assembly, inspection, packing, delivery, installation and commissioning of an auxiliary boiler for use at the Philippine Associated Smelter and Refining Corporation (PASAR) in Leyte, Philippine’s.

1.2. Applicable Standards

The Supplier shall comply with the rules and provisions of the latest editions and amendments of the specifications and standards nominated in the technical specification. Where there is no applicable specification or standard nominated, the work shall be provided in accordance with the appropriate European, US or other approved standard, applied in that order of priority. Where a standard is specified on the Contract Drawings, it shall apply in precedence to other standards.

Compliance with Standards and Regulations shall include all published amendments to the date of tender.

Where a seller is supplying equipment to a standard design, the seller’s standards shall be acceptable, provided that a list of specifications and standards is submitted in writing and approved by the PASAR project department.

2.GENERAL SITE CONDITIONS

The equipment will be required to operate in a tropical environment, within a smelter plant. The equipment location is outdoors. The ambient air will typically be dusty and contain traces of SO2.

Specific conditions are provided in the table below.

|

ITEM |

DESCRIPTION |

DATA |

|

1.0 |

SITE CONDITIONS FOR DESIGN |

|

|

1.1 |

Atmospheric Conditions |

The site is a smelter site located next to the sea. It is a marine environment. In addition, the ambient air contains process generated dusts and will contain gases including sulphur dioxide. |

|

1.2 |

Plant Design Life (minimum) |

10 Years for structure and mechanical equipment (diesel motor, hydraulic components, gear reducers, travel components, etc).3 years for belts, apron feeder, etc.1 year for wear components – screens, grizzly bars, chute liners, etc. |

|

1.3 |

Bearing Service Life – L10 basis |

Not less than 25,000 hrs |

|

1.4 |

Altitude (a.m.s.l.) Ambient Conditions |

20 m |

|

1.5 |

Temperature Range |

Maximum temperature: 41 ℃ |

|

Minimum temperature: 22 ℃ |

||

|

Mean temperature : 29 ℃ |

||

|

1.6 |

Relative Humidity (Range) |

1013.25 mbar up to 95% Outdoors |

|

1.7 |

Seismic/Geographic conditions |

|

|

|

Seismic Coefficient |

: 0.3 |

|

|

Earth sustaining |

: 20 tons/m2 |

|

|

Earthquake level |

: Zone 4 (seismic map of Phil) |

|

|

Seismic dynamic peak acceleration |

: 4.0m/s2” |

|

1.8 |

Installation Outdoors/Indoors |

Outdoors |

|

1.9 |

Noise Limit |

85 dB (A) at 1 metre when operating and processing material |

|

1.10 |

Power supply |

|

|

|

Control |

: 110 V,60Hz; |

|

|

Lighting |

: 220 V,60Hz; |

|

|

Low voltage |

: 440V,60Hz;+/-4% |

|

|

Middle voltage |

: 3.3kV,60Hz; |

|

|

High voltage |

: 22kV,60Hz; |

|

1.11 |

DCS or PLC signal specification |

|

|

|

Analogue input signals: |

: 4~20mA.DC |

|

|

|

: T/C (K or S) |

|

|

|

: RTD (Pt100) |

|

|

Analogue output signals: |

: 4~20mA.DC |

|

ITEM |

DESCRIPTION |

DATA |

|

2.0 |

OTHER REQUIREMENTS |

|

|

2.1 |

Medium for Equipment Cooling |

TBC |

|

2.2 |

Equipment Paint Colours |

Manufacturer’s standard if it meets or exceeds the Pasar Specification: PASAR Standards MS 13 REV 03 - GENERAL SPECIFICATION GENERAL SPECIFICATION FOR PAINTING; PASAR Standards MS 13 A REV 01 - GENERAL SPECIFICATION COLOR SYSTEM OF PAINTING |

|

2.3 |

Minimum level of protection for electrical equipment (control panels, limit switches, controller equipment, lights, etc.) |

IP65 (IP 66 preferred) |

3.SCOPE OF SUPPLY

3.1 Scope

The scope of work of the Contractor shall include the supply of all materials, labor, tools and equipment consumables, supervision, safety paraphernalia and all other activities necessary for and/or incidental to complete the Supply and Installation of Auxiliary Boiler for PASAR Smelter Plant Isabel, Leyte all in accordance with the scope of works. The Work shall include, but not necessarily be limited to the following:

|

SUPPLY SCOPE |

||

|

DESCRIPTION / INCLUSIONS |

EXCLUSIONS |

REMARKS |

|

Complete boiler with all required feed systems, blowers, fans and safety and control devices. |

Civil foundations, building / roofing structures and ancillary pipe supports. |

In accordance with specifications PASAR Standards MS-1M - GENERAL SPECIFICATION ENGINEERING CRITERIA FOR MECHANICAL |

|

Installation and commissioning of all mechanical equipment, piping, valves, instrumentation and system wiring. |

Supply of power & services. |

Quote daily rate for site erection & commissioning |

|

Packing for marine freight to Philippines |

|

Packaging to international accepted standards as per attached document |

|

Technical documentation set |

|

As per requirements in Section 6.0. |

4.DATA SHEET

|

DESCRIPTION |

DATA |

|

1.0 OPERATING DATA FOR BASE OFFER |

|

|

NUMBER OF SYSTEMS: |

One (1) |

|

DESCRIPTION: |

|

|

STEAM GENERATION: |

22 tph |

|

STEAM PRESSURE: |

42 – 45 Bar |

|

MAXIMUM OPERATING PRESSURE: |

52 Bar |

|

WATER CIRCULATION: |

Natural Circulating |

|

FEED WATER TEMPERATURE: |

110° C |

|

FUEL: |

Bunker Fuel during normal operation, Diesel Fuel during start-up |

|

BURNERS: |

Separate burners for non-atomizing + diesel fuel (during start-up) |

|

ATOMIZING: |

Steam or compressed air (option) |

|

PAINT SYSTEM AND MATERIALS |

Equipment should be protected by the manufacturer’s standard paint system suitable for a corrosive / marine environment. Fasteners shall be manufactured from corrosion resistant materials. |