What are the common blowdown valves of oil steam boiler

In order to ensure the normal operation,the oil fired steam boiler needs to be equipped with the blowdown device,generally,the blowdown device locates in the lowest place of boiler drum and header,consists of blowdown valves and pipes.In this text,ZG will introduce some common blowdown valves of oil fired steam boiler.

Cock-type blowdown valve

The Cock-type blowdown valve mainly consists of valve core and valve body,the valve has simple structure,but its valve core easily has thermal expansion,which makes it difficult to rotate,so it is rarely used now.

Rack gate type blowdown valve

The rack gate type blowdown valve is mainly composed of rack,gate,valve seat,valve body and other parts,belongs to the quick opening types.

Swing type blowdown gate

The swing type blowdown gate mainly consists of handle, shaft,valve plate and valve body and other parts,the valve is agile,has good blowdown effect,belongs to quick opening types.

Slowly opening gate type blowdown valve

The slowly opening gate type blowdown valve approximately has the same structure with the rack gate type one,compared with quick open valves,its opening and closing time required is longer,belongs to the lowly opening types.

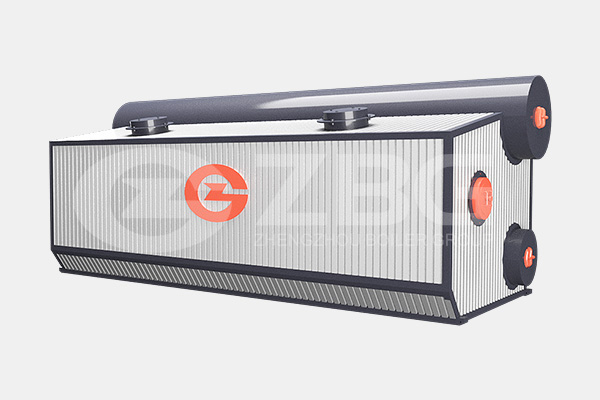

ZG,as a professional oil fired boiler manufacturer,has developed and exported many oil fired boilers in recent years,ZG WNS oil fired steam boiler is one of the most popular at home and abroad,has acquired the customer's consistent good opinion.Pleasure feel free to contact us for more details about that!