Any question, please contact us for free. Phone number: +86-371-86686767 Skype: zgboiler Email:zbgboiler@zzboiler.com

Biomass Boiler for Feed Mill in Tanzania

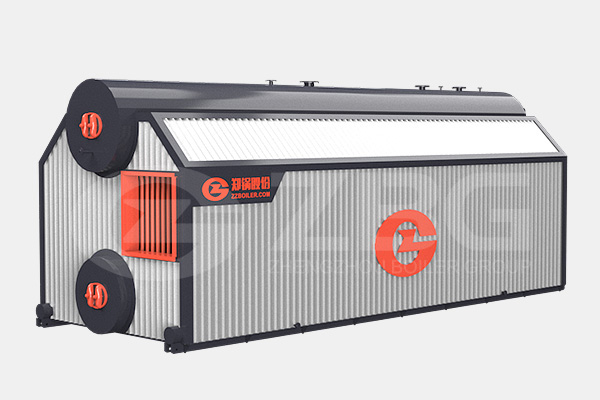

ModelDZL4-1.25-T

Capacity4 tons

Applicationfeed processing

This production line was invested in Tanzania by Tanzania customers who finally chose ZBG’s solution after many comparisons and analyses.

We know that steam is very important energy in feed processing mill, the industrial steam boiler is the very equipment to supply high temperature steam. While ZBG DZL packaged boiler can burn both coal and biomass fuel with a high efficiency. Compact structure and easy installation ensure efficient, clean, economic, safe and stable boiler operation, so it is widely used as an energy-saving and environment-friendly equipment in industry.

Biomass boiler benefits

1.Renewable Energy Source-- biomass energy is generated from organic material, plant or animal waste, which is burned to provide energy, e.g. heat & electricity.

2.Better for the environment than fossil fuels--the burning of biomass does release carbon dioxide but captures carbon dioxide for its own growth.

3.Less Dependency on Fossil Fuels--using biomass as an alternate source of fuel reduces our dependency on fossil fuels which is better for the planet and more cost effective.

4.Very Easily Available--biomass is cheap and readily available source of energy

5.Reduce Landfills--by burning biomass for energy, we can take waste that is harmful to the environment and turn it into something useful.

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

RELEVANT CASES

RELEVANT PRODUCTS

-

Corner Tube Biomass Fired Boiler

Pressure:≤5.29MPa

Fuel:Rice Husk, Wood Pellet, Bagasse

Capacity:10-160 t/7-112 MW -

Biomass Power Plant Boiler

Pressure:≤5.29MPa

Fuel:Rice Husk, Straw, Wood Pellet, Bagasse

Capacity:10 - 75 t/ 7-52.5 MW -

Biomass Fired CFB Boiler

Pressure:≤5.29MPa

Fuel:Biomass,Rice Husk,Palm Kernel

Capacity:20-280 t/ 14-196 MW -

SZL Water Tube Boiler

Pressure:≤1.6MPa

Fuel:Biomass Fuel, Rice Husk, Bagasses

Capacity:6-30 t/ 4.2-21 MW

Get An Instant Quotation

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

HOW TO CONTACT

-

E-mailzbgboiler@zzboiler.com

-

Tel0086-371-86686767

-

Fax0086-371-67838093

-

Skype17719993430

-

Whatsapp+86 17719888549

-

AddZhengzhou,Henan,China